Automation is propelling major advancements in a number of industries, including rock crushing, in today’s fast-paced industrial world. Once a symbol of unbridled mechanical might, the conventional rock crusher is changing quickly. Engineers are incorporating modern automation technologies to boost productivity, security, and effectiveness. The automated rock crusher is raising the bar for productivity in a variety of industries, including aggregate manufacturing, mining, and construction. If you’ve lately looked for a rock crusher near me, you’re probably going to come across cutting-edge, clever equipment that takes advantage of these fascinating developments.

A Historical Perspective On The Conventional Rock Crusher

In the past, rock crushers functioned with little assistance from technology. The design concept for jaw crushers, cone crushers, and impact crushers was straightforward: use as much force and pressure as possible to break down hard materials. To get the required outcomes, operators had to manually tweak settings and visually inspect wear and tear, depending on their intuition and expertise. Although this method completed the task, it often resulted in inefficiencies, irregular production, and increased maintenance expenses.

Automation’s Ascent In Rock Crushing

Automation is emerging as a major force behind innovation in rock crusher design as a result of developments in Industry 4.0 and the Industrial Internet of Things (IIoT). Nowadays, even small and portable crushers have intelligent characteristics, thus automation is no longer only found in bigger processing facilities. Let’s examine the main ways that automation is changing the rock crushing sector:

- Real-Time Monitoring And Intelligent Sensors

A variety of digital sensors are now standard on modern rock crushers, offering real-time information on anything from load and throughput to temperature and vibration. These sensors aid operators in performance optimization, failure prediction, and machine health monitoring.

For instance, automatic sensors can identify if the jaw plates are wearing unevenly while you’re running a jaw crusher in a quarry and notify you before a failure happens. Operational dependability is improved, and downtime is greatly decreased by this proactive maintenance.

- Automated Modifications For Reliable Results

One of the most remarkable capabilities of automated rock crushers is their capacity to automatically modify parameters to ensure constant output. Automation systems can react quickly to variations in material type, hardness, and moisture content, whether modifying the rotor speed in an impact crusher or the closed-side setting in a cone crusher.

This removes uncertainty and guarantees consistency in the size and quality of the finished product, which is crucial in applications including road construction and construction.

- Remote Control And Operation

The days of operators having to be physically close to the machine at all times are long gone. These days, a lot of rock crushers can be controlled remotely. Operators may start or stop equipment, change settings, and even do diagnostics using a desktop interface, tablet, or smartphone.

By keeping employees out of potentially hazardous areas, this not only increases safety but also boosts productivity, particularly in bigger businesses with many crushers operating.

- Environmental Advantages And Energy Efficiency

In addition to improving performance, automation also promotes sustainability. Compared to their manual equivalents, current rock crushers use a lot less energy since they automatically optimize power utilization depending on load. Some systems even include energy recovery modules or renewable energy sources.

Furthermore, automated systems guarantee accurate and effective material processing, which is essential in sectors looking to lessen their environmental impact and contribute to waste reduction.

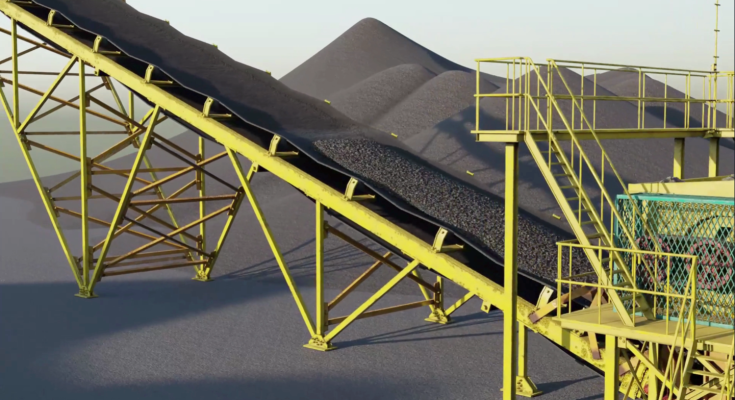

- Connectivity To More Comprehensive Plant Automation Systems

Rock crushers aren’t solitary devices anymore. These days, they are made to blend in well with bigger automated processing facilities. Automation enables coordinated operations across all components, including feeders, separators, conveyors, and screeners. This all-encompassing strategy guarantees that production is maximized and bottlenecks are reduced.

The Design Of Rock Crushers In The Future

We may anticipate increasingly more intelligent rock crushers with stronger AI, improved diagnostics, and more interoperability as automation technologies advance. Digital twin modeling, voice control, and maintenance assistance for augmented reality are all on the horizon. These innovations will revolutionize sectors that rely on effective material processing.

In conclusion

Automation is ushering in a new age of smarter, safer, and more efficient machinery, which is radically changing the design of rock crushers. These developments, which range from remote control and real-time monitoring to predictive maintenance and energy optimization, are changing the way crusher equipment is used in the field. If you’re looking for a “rock crusher near me,” you may want to look at automated solutions. Although they could be more expensive initially, the savings and performance gains over time make the investment worthwhile.