Modern construction demands innovative solutions that streamline processes while maintaining structural integrity. The evolution of reinforcement connection methods brings forward advanced solutions that transform how large-scale projects come together, particularly in demanding construction environments.

Time-tested durability in construction

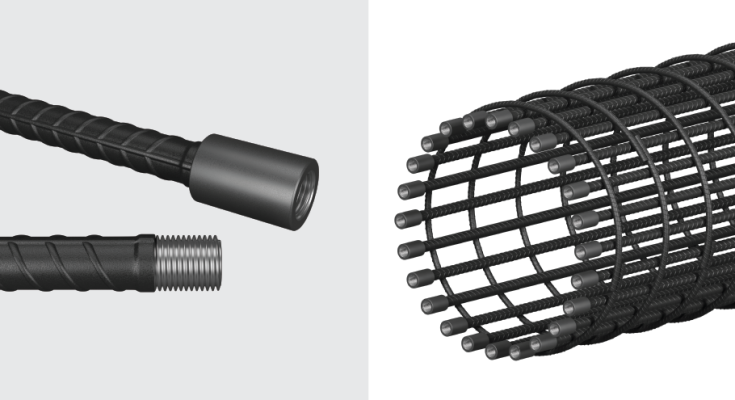

Traditional reinforcement methods faced limitations in complex structural applications. Engineers and construction teams needed better solutions for connecting reinforcement bars efficiently. The precast coupler emerged as a pivotal innovation, delivering consistent performance across varied environmental conditions while reducing installation complexity.

Essential components in modern structures

Structural integrity starts with proper reinforcement connections. These mechanical connections create strong bonds between reinforcing bars, maintaining the intended load transfer throughout the structure. Project teams rely on detailed specifications to ensure each connection point meets design requirements.

Project safety enhancement

Safety remains paramount in construction projects. The precast coupler installation process minimizes working at heights and reduces manual handling risks. Teams complete connections faster with mechanical systems compared to traditional methods, decreasing exposure time in hazardous areas while maintaining quality standards.

Material performance benefits in construction

- Enhanced load distribution across connection points

- Reliable performance in seismic conditions

- Superior fatigue resistance under dynamic loads

- Consistent strength development

Installation advantages on-site

- Reduced workspace requirements

- Simplified quality verification process

- Lower skill requirements for installation teams

- Minimized weather impact on connections

Quality control improvements

- Clear visual inspection criteria

- Standardized installation procedures

- Documented performance metrics

- Reliable testing methods

Project timeline optimization

Construction schedules benefit from streamlined processes. Mechanical connections eliminate curing time requirements, allowing immediate loading after proper installation. This acceleration helps projects stay on track while maintaining structural requirements and safety standards.

Cost-efficiency in large projects

Initial material costs balance against labour savings and schedule improvements. Faster installation reduces overall project duration, leading to earlier project completion and reduced site overhead costs. The elimination of specialized labour requirements further contributes to the project economy.

Integration with modern construction methods

Digital design tools incorporate connection details early in the planning process. This integration ensures proper coordination between precast elements and site-cast components. Advanced modelling helps identify potential conflicts before construction begins.

Maintenance considerations

Long-term performance relies on proper initial installation. Regular inspections follow standard procedures, with clear acceptance criteria for ongoing structural assessment. Documentation requirements support future maintenance planning and structural modifications. Innovation continues in connection with technology. Research focuses on improving installation efficiency while maintaining structural performance. New materials and designs emerge to meet evolving construction requirements and building codes.

Implementation best practices

- Detailed specification review

- Proper storage and handling

- Installation team training

- Quality control documentation

- Regular inspection programs

Structural performance validation

Testing protocols verify connection performance under various load conditions. Laboratory results translate to field applications through standardized procedures. This validation ensures consistent performance across project applications.

Industry standards alignment

Building codes recognize mechanical connection systems. Design standards provide clear guidelines for specification and implementation. These frameworks support proper application across different project types and locations.

Performance improvements in large-scale construction projects stem from technological advances in reinforcement connections. Projects benefit from faster construction, improved safety, and reliable structural performance. As construction methods evolve, connection systems continue advancing to meet industry needs while maintaining high safety and performance standards.