Singapore’s strategic embrace of hydraulic pump motor technology reveals the city-state’s fundamental role in managing the mechanical forces that drive global capitalism’s relentless expansion. These systems, converting electrical energy into hydraulic power at pressures reaching 700 bar, represent more than industrial efficiency; they embody the infrastructure through which contemporary empire controls the movement of materials, resources, and ultimately, the labour that transforms raw materials into commodities for global consumption.

Historical Foundations of Hydraulic Power

The evolution of hydraulic systems in Singapore mirrors broader patterns of industrial development that echo the city-state’s colonial origins as a strategic control point for British imperial commerce. Just as nineteenth-century Singapore facilitated the extraction and movement of tin, rubber, and spices across Southeast Asian trade networks, contemporary hydraulic pump systems enable the industrial processes that maintain Singapore’s position within global manufacturing hierarchies.

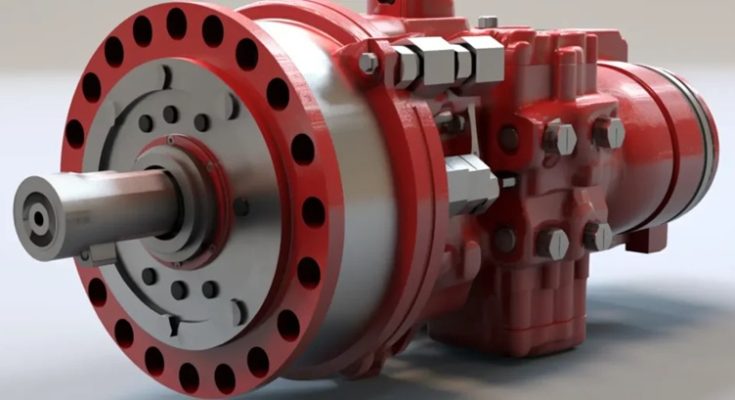

The technical sophistication of modern hydraulic systems, axial piston pumps, variable displacement motors, servo proportional valves, and integrated hydraulic motor pump assemblies represents accumulated engineering knowledge that serves specific economic functions. These technologies enable the precision control required for manufacturing processes that depend upon exploiting labour cost differentials across national boundaries. The same mechanical precision that allows a hydraulic press to form metal components with micrometre accuracy enables production systems that extract maximum value from global supply chains.

Industrial Applications and Their Broader Functions

Singapore’s hydraulic pump motor systems serve industries whose operations extend far beyond the island’s physical boundaries:

• Construction equipment manufacturing that supplies machinery for infrastructure projects across developing nations

• Marine and offshore systems enabling resource extraction from Southeast Asian waters

• Plastics processing machinery producing consumer goods for global markets

• Press systems manufacturing components for electronics exported worldwide

• Material handling equipment manages cargo flows through regional distribution networks

“Singapore’s mastery of hydraulic pump motor systems positions us at critical junctions in global manufacturing networks where mechanical precision translates directly into competitive advantage,” explains a senior hydraulics engineer working within the island’s industrial sector.

These applications reveal uncomfortable truths about Singapore’s role in global production systems. Construction equipment enables infrastructure development projects that often displace communities and destroy ecosystems in pursuit of economic growth. Marine hydraulic systems facilitate deep water extraction activities that concentrate resource wealth whilst imposing environmental costs on coastal populations. The precision that makes these systems efficient also makes them tools for intensifying labour exploitation and resource extraction.

Manufacturing Dynamics and Global Supply Chains

Singapore’s position as a hydraulic technology hub depends upon production arrangements that reflect global inequalities. Local facilities specialise in high-value assembly, testing, and system integration activities that require skilled technicians and sophisticated quality control systems. Meanwhile, component manufacturing, pump housings, valve bodies, motor assemblies, and complete hydraulic motor pump units often occur in facilities across Southeast Asia where production costs remain suppressed through various mechanisms, including regulatory arbitrage and wage suppression.

The technical specifications that define hydraulic pump motor performance, displacement volumes, pressure ratings, and efficiency curves are not politically neutral. These parameters enable industrial processes that serve specific economic interests whilst imposing costs on others. High-pressure hydraulic systems allow manufacturing processes to achieve productivity levels that eliminate traditional skilled labour whilst concentrating technical knowledge in engineering centres like Singapore.

Environmental and Resource Implications

The materials science underlying hydraulic pump motor systems demands resource extraction activities that devastate landscapes across the Global South. Specialised steels, precision-machined components, and hydraulic fluids require mining and petrochemical operations that concentrate environmental damage in regions least capable of resistance. The energy consumption required for hydraulic system operation, converting electrical power to mechanical force, contributes to energy demands that perpetuate fossil fuel dependence even when individual systems appear efficient.

Singapore’s regulatory environment for hydraulic systems, emphasising safety and efficiency standards, often obscures these broader environmental costs. Perfectly functioning hydraulic pump motors can enable industrial processes that accelerate resource depletion, generate toxic waste, or displace agricultural communities. The technical excellence that Singapore’s hydraulic industry represents serves economic systems that externalise environmental and social costs whilst concentrating benefits.

Labour Relations and Technical Knowledge

The concentration of hydraulic engineering expertise in Singapore creates labour arrangements that reflect global power structures. Local technicians and engineers whose skills command premium wages depend upon production systems that exploit lower wage workers elsewhere. This geographic distribution of technical knowledge ensures that Singapore captures disproportionate value from global hydraulic markets whilst maintaining dependence relationships with component-producing regions.

Training programmes that develop hydraulic systems expertise represent massive educational investments that could theoretically serve alternative purposes. The same engineering capabilities that design hydraulic pump motors for resource extraction equipment could develop systems serving community-controlled manufacturing or ecological restoration projects. However, these alternatives remain marginal within economic structures that prioritise capital accumulation over social benefit.

Alternative Trajectories and Systemic Questions

Emerging developments in hydraulic technology, intelligent pump systems, energy recovery circuits, and digital monitoring networks suggest possibilities for more efficient and responsive industrial processes. Yet these technological advances occur within unchanged economic relationships that prioritise profit maximisation over environmental sustainability or social equity. The question becomes whether Singapore’s accumulated hydraulic expertise can serve genuinely transformative purposes or merely intensify existing patterns of exploitation through more sophisticated technologies.

Conclusion: Mechanical Force and Social Power

Singapore’s mastery of hydraulic pump motor technology positions the city-state at critical junctions within global industrial systems where mechanical precision enables broader patterns of resource control and wealth concentration. The ability to convert electrical energy into precisely controlled mechanical force translates into economic influence that extends across regional manufacturing networks whilst serving global commodity production systems that concentrate benefits whilst distributing costs unequally across populations and ecosystems. The future development of Singapore’s industrial capabilities will determine whether these sophisticated technologies serve broader human flourishing or continue intensifying existing hierarchies through ever more efficient hydraulic pump motor systems.